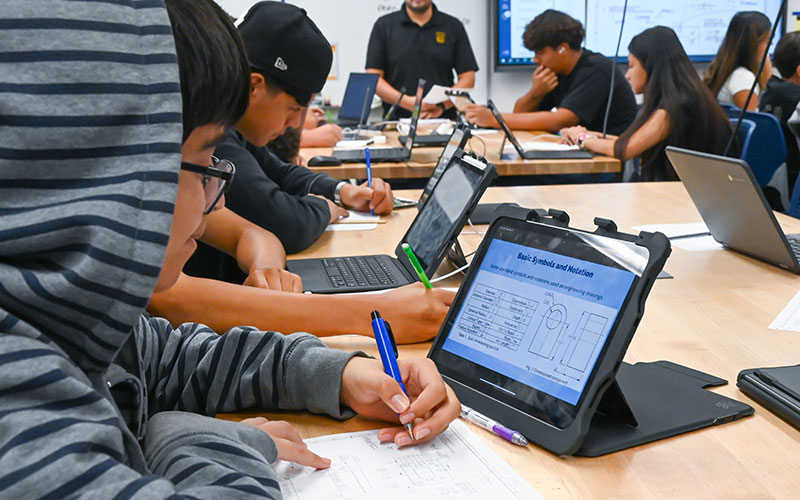

CTE Pathways: Manufacturing & Product Development

Machining & Forming Technologies Pathway

This pathway is designed as a survey of machine tool technology. Student focus is on traditional machine tool technologies. Coursework includes setup and operation of the engine lathe, the milling machine, the drill press, and sawing and cutoff machines. Additional topics incorporate the calculation and setup of speeds and feeds, and measurements. Students considering Machining courses develop strong math fundamentals by learning plotting and mapping coordinates in the CNC processing. Communication and collaboration skills center on working with conventional and CNC machines for the safety of self and others.

Courses

YEAR 1: Forming and Machining I

Course Description

This course meets the University of California G-Elective requirements.

YEAR 2: Forming and Machining II

Course Description

This capstone course provides Advanced Manufacturing content, skill development and leadership training in a commercial machine ship environment which prepare students to pursue industry certifications, employment, and a postsecondary degree.

This course meets the University of California G-Elective requirements.

Outcomes

Students who complete Machining & Forming I may apply to receive credit for the Cerritos College course MTT 100 Machine Tool Introduction.

For More Information

Contact:

Frank Menjivar, Teacher

fmenjivar@dusd.net

Mechatronics Pathway

This one-course pathway provides students with a hands-on environment to work with technological systems. Students will dive into the engineering process, solving system problems with creative solutions. The pathway sets students up for success as they continue down the career path via academic, vocational or technical courses.

Courses

Course Description

This course meets the University of California D-Science (engineering) requirements. This course also receives UC Honors credit.

YEAR 2: Honors Mechatronics Capstone Coming Fall 2026

For More Information

Contact:

Aaron Tostado, CTE Teacher

atostado@dusd.net

Outcomes

Welding & Materials Joining Pathway

Careers in welding are in demand. With our Welding and Materials Joining pathway, students can begin the training they need to succeed in the field early on with the same equipment used by industry professionals. The course prepares students for welding jobs right out of high school or to continue their education at schools like partner Cerritos College.

Courses

Course Description

This course meets the University of California G-Elective requirements.

Course Description

This course meets the University of California G-Elective requirements.

Outcomes

Students who complete Welding and Materials Joining I will take the exam to receive OSHA 10- General Industry Certification.

For More Information

Bryan Mazariegos

bmazariegos@dusd.net

Learn More: CTE Pathways at Warren

Each CTE Pathway is industry-focused and usually consists of 2-3 courses. The last course in the pathway is the capstone. When students complete a course they may receive college credit or receive an industry certificate. Click on each industry below to see details about the courses and outcomes.